Pot Bearing

PRODUCT OVERVIEW

VHB Pot bearings made by Vinh Hung Investment and Production Company Limited (Vinh Hung IP) are in compliance with standards: TCVN 11823-2017, TCVN 10268-2014, TCVN 10269-2014, AASHTO LRFD: 2007 – Section 18, BS 5400, EN 1337, KS F4424.

VHB Pot bearings are capable of withstanding high loads, displacements and wide angle rotation. This type of bearing is suitable for middle-range span structure, continuous bridge structure etc. with a load capacity of 60000kN or above depending on projects’ requirements.

VHB Pot bearings have well-shaped structure, superior design, which is convenient for installation and maintenance during operation.

Certificate of VHB Pot bearing products according to TCVN 10268:2014 standard

1. CLASSIFICATIONS

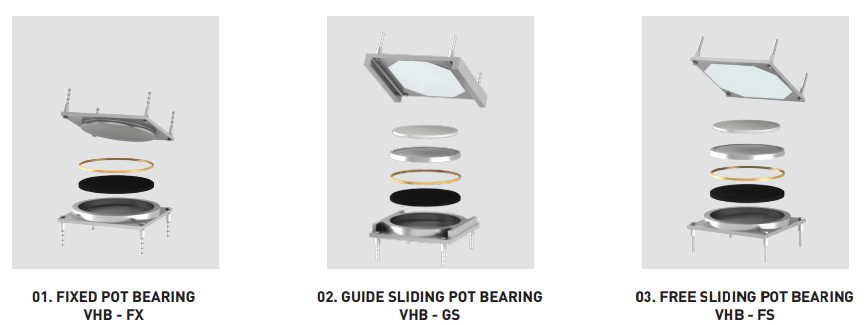

Pot bearings are divided into 2 main types: Fixed pot bearing and sliding pot bearing.

- Fixed Pot bearing: The bearing only allows the head of structure to have rotary movement and transfers the pressure through a fixed point.

- Sliding Pot bearing: This type of bearing, including free sliding bearing and guided sliding bearing, allows the head of structure to have both rotary movements and transversally or multidirectional movements.

2. PRODUCT COMPONENTS

VHB Pot bearing is comprised of 4 main parts: top plate, piston, pot plate and elastomeric pad. The elastomeric pad is placed inside of pot plate, under the pressure of the load, the elastomeric pad experiences the temporary deformation inside the pot plate volume, it is capable of withstanding the forces and allows the movement as well as rotation along horizontal axis.

Piston and pot plate work as the connecting parts between the structures. Besides, the plus guiding bar can be designed to limit or allow the movements as required from the structures.

To ensure the long-life durability, VHB Pot bearings are protected against corrosion by the following methods: two-component Epoxy coat, PU-based painting (Polyurethane), hot dip galvanization according to ASTM A123 standard and especially the Al – Mg spraying method (at the ratio of 95% Al and 5% Mg) which ensure the anti-corrosion durability of up to 100 years, proven by salt-spraying test in 6000 hours (8-hour dry-wet cycle repetition) according to ASTM B117 standard.

-159x76-159x76.png)