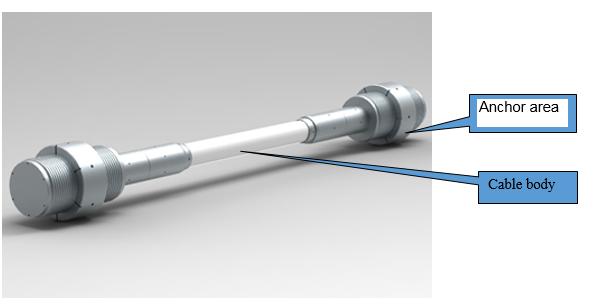

PWS CABLE SYSTEM

PWS cable system

Structure of a PWS cable system:

Consisting of durable 7mm diameter cable wires of 1770 Mpa, or 1860Mpa ... galvanized with ASTM A475 standard, the cable wires are twisted slightly together with an angle of 2-4 degrees.

Cable bundle was sheated with 2 layers of HDPE protection (inner layer is black, outer layer creates color as required by the investor) by extrusion method.

Cross section of PWS cable system

Cross section of PWS cable system

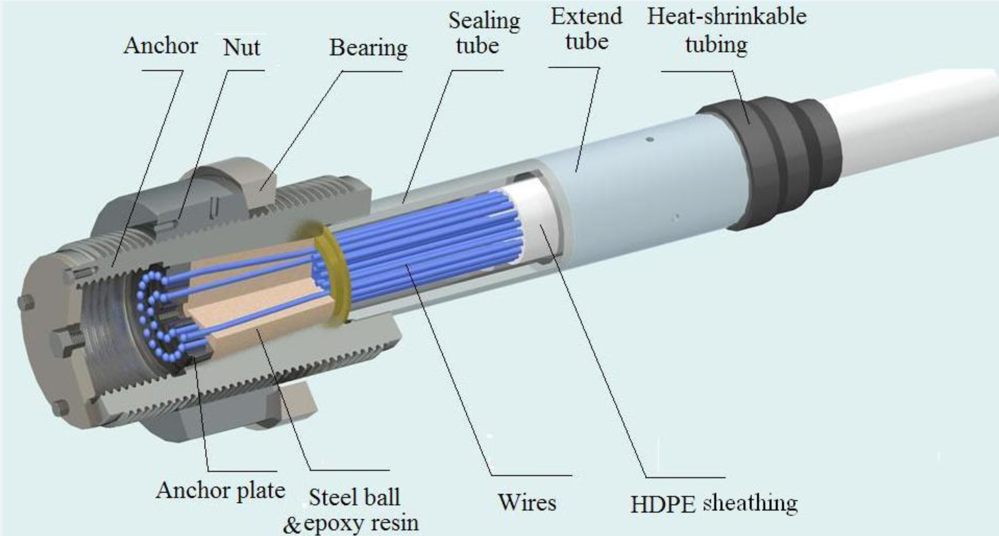

Cable anchorage structure for PWS cable system:

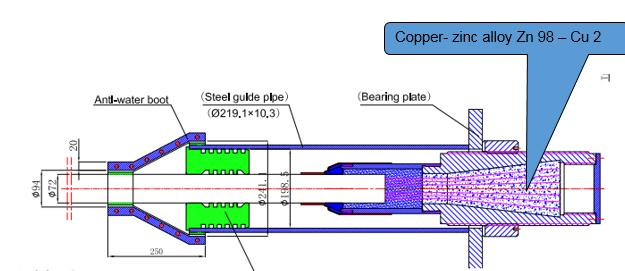

There are two main methods for performing anchorage structure for a PWS cable system

- The bonding method using anchorage head in combination with steel balls and Epoxy glue:

- The bonding method using zinc & copper alloy:

.jpg)

Physical properties:

- Modulus of elasticity: E = 205 Gpa,

- Tensile strength: Fpu = 1670, 1770, 1860 or 1960 Mpa

- Satisfying fatigue requirements of FIB, PIT and SETRA: Fatigue test 2 million times with yield stress amplitude of 200MPa.

Advantages:

- Small cable bundle diameter, good ability to be influenced by rain and win

- Due to the in-plant production, the quality control of cable bundles is also better (because there was an experiment/testing to pull the cable before the factory was shipped).

- For small and short cable bundles, the construction is relatively easy due to the need for few construction machines and tools

Application:

- Cable for steel arch bridges, steel concrete pipe arch bridges.

- Cable stayed for stayed-cable bridge, extradosed bridge.

-159x76-159x76.png)