Pendulum bearing

PRODUCT OVERVIEW

VHPD Pendulum bearings manufactured by Vinh Hung Investment and Production Company Limited (Vinh Hung IP) is capable of withstanding high loads and movements and suitable for structures requiring big rotation angle in all directions and structures in seismic zone. VHPD Pendulum bearings are designed and manufactured according to current standards such as EN 15129, etc.

VHPD Pendulum bearings with curved surface sliders reliably serves the following main functions:

- Under service conditions, the devices are designed to transmit vertical forces and allow for horizontal displacements.

- In case of an earthquake, lateral flexibility is achieved through the sliding of an element along the primary curved surface.

- Energy dissipation is produced by the dynamic friction between the sliding stainless steel surface and the high performance sliding material.

- Finally, the re-centering function is given by the combination of gravity and geometry of the device’s design.

3D image of the product

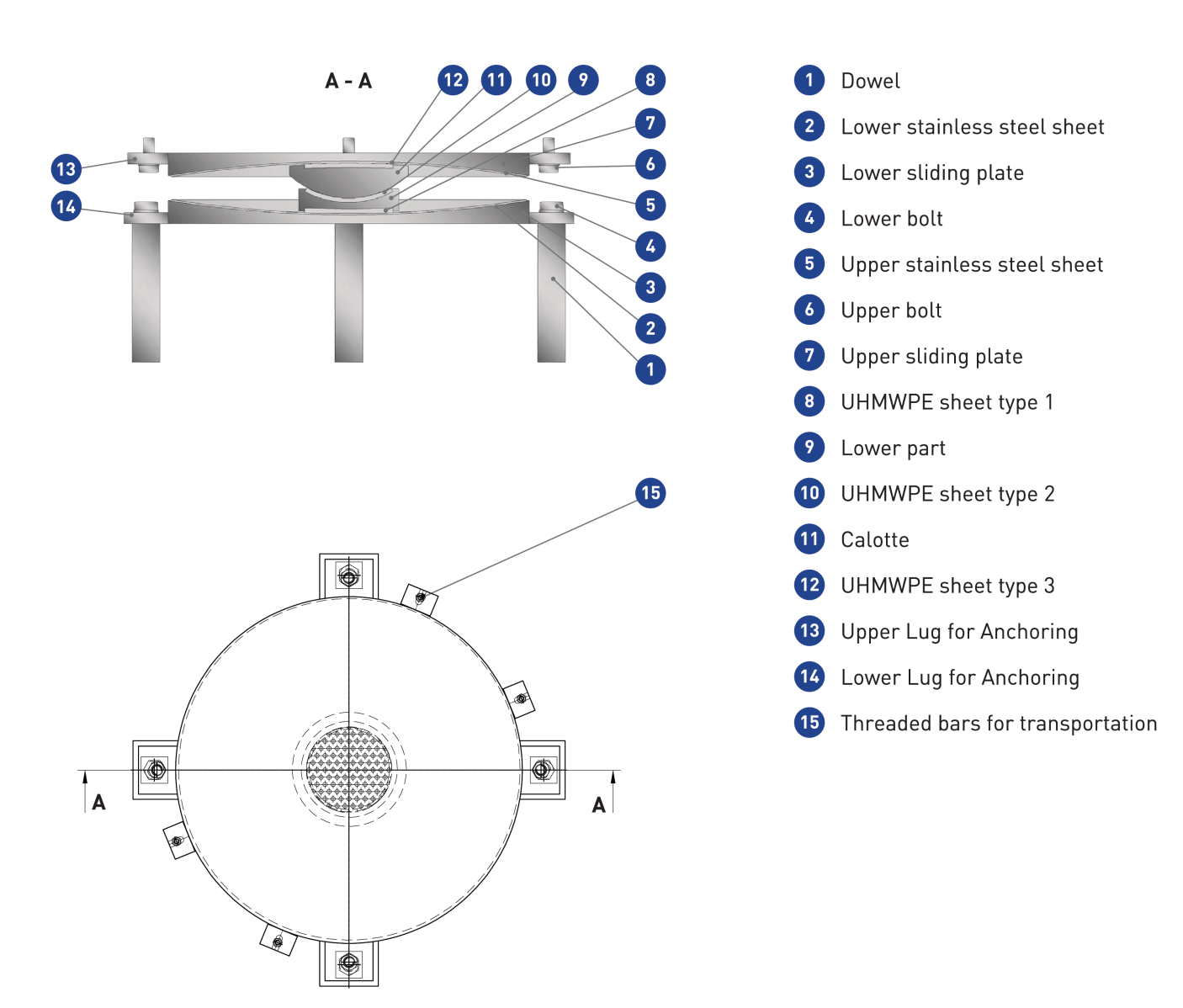

PRODUCT COMPONENTS

VHPD Pendulum bearings are designed based on the working principle of a pendulum. They allow the horizontal displacement of structure, providing the required shift in the natural period of the structure. Once activated by an earthquake, the isolators will allow the decoupling of the supported structure from the ground motion. After the seismic event, the restoring force due to gravity will bring it back towards the center position. The performance of the device mainly depends on its radius of curvature and the coefficient of friction.

VHPD Pendulum bearing includes two primary curved sliding surfaces. This allows higher horizontal displacements to be facilitated with smaller dimensions. It includes a rocking element equipped with an articulation element that allows the bearing to accommodate rotations. This is an essential feature, especially for bridges which require high displacements and significant rotational capacity.

To ensure the long-life durability, VHPD Pendulum bearings are protected against corrosion by the following methods: two-component Epoxy coat, PU-based painting (Polyurethane), hot dip galvanization according to ASTM A123 standard and especially the Al – Mg spraying method (at the ratio of 95% Al and 5% Mg) which ensure the anti-corrosion durability of up to 100 years, proven by salt-spraying test in 6000 hours (8-hour dry-wet cycle repetition) according to ASTM B117 standard.

-159x76-159x76.png)