HOW A VINH HUNG’S BRIDGE BEARING CONTROLLED QUALITY?

In purpose of supervising the manufacturing stages of bridge bearing and bringing trust to customer, Vinh Hung has invested quality checking devices for all manufacturing stages and a laboratory with state-of-art equipment to control quality comprehensively, from raw materials, to manufacturing process and completed products.

Specifically, Vinh Hung bridge bearings will be strictly quality checked with about 20 test criteria including 3 stages:

- Testing raw materials for bridge bearing manufacture: All raw materials including steel, rubber, brass ring, PTFE, etc. are checked origin, identify and quality before manufacturing begins.

- Testing during manufacturing process: The semi-finished products during the production process are taken samples and tested at the in-house laboratory to control important specifications. Some test criteria include: post-weld mechanical properties determine, non-destructive testing (NDT) of welds, protect coating quality determine, etc.

Testing raw materials and semi-finished products:

- Test of finished bridge bearings: Vinh Hung bridge bearings after manufacturing completes are tested at in-house laboratory. Besides, several products commanded by investors or third-party inspector are independently tested in third-party laboratory. Testing criteria includes vertical load compression test (short-term, long-term), horizontal load test, rotation angle, shear modulus, coefficient of friction.

Testing bridge bearings in Vinh Hung:

Testing bridge bearings in National road construction equipment materials laboratory Vilas 276:

The whole testing process is carried out according to popular standards such as AASHTO LRFD - USA, EN 1337, AASHTO M251; ASTM D4014; ASTM D 5977; TCVN 10269; TCVN 10308 and supervised by independent third party appointed by the contractor. This is one of important stages in quality management system ISO 9001:2015 and welding quality management system EN 3834.

By 2022, Vinh Hung factory has manufactured and tested quality more than 12.000 pot bearing for the market, among them pot bearings with load capacity of up to 34,500kN are exported for Malolos-Clark Railway, Philippines.

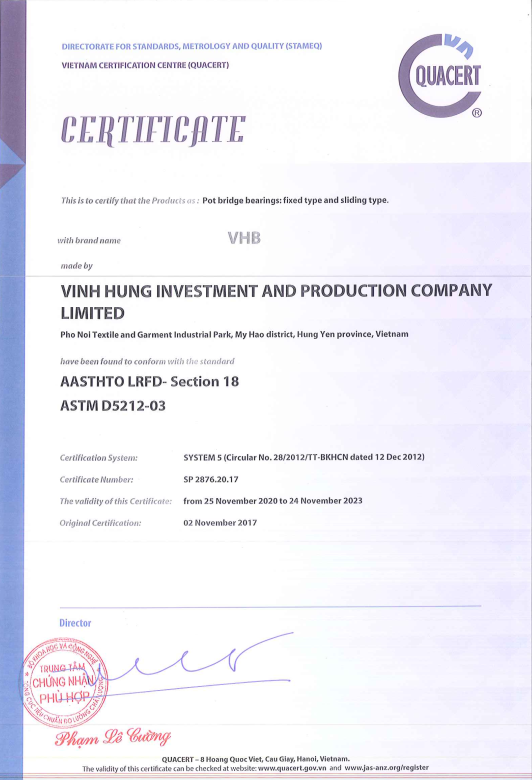

Certificates of conformity for Vinh Hung pot bearings and elastomeric bearings:

|

|

|

|

-159x76-159x76.png)